X

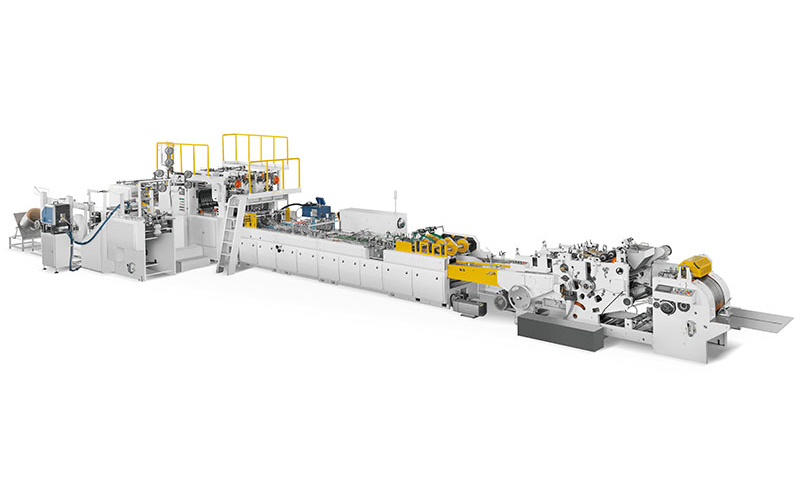

KL-220H

Main Technical Parameters

| Model | KL-220H |

| Paper Bag Width | 130-250mm/5.11-9.84 inch |

| Feed Paper Width | 490-770mm/19.29-30.31 inch |

| Feed Paper Length | 260-450mm/10.23-17.71 inch |

| Paper Weight | 100-190g/m2 |

| Recommend that paper thickness above 200gsm die cutting before operation) | |

| Bag Mouth Fold Width | 40-50mm/1.57-1.96 inch |

| Handle Patching Length | 114mm/4.48 inch |

| Handle Patching Width | 40-50mm/1.57-1.96 inch |

| Patch Paper Thickness | 100-140g/m2 |

| Patch Paper Roll Diameter | φ1000mm |

| Patch Paper Roll Width | 80-100mm/3.15-3.94 inch |

| Handle Rope Diameter | φ4-6mm/0.16-0.24 inch |

| Handle Rope Height | 160-185mm/6.29-7.28 inch |

| Glue Type |

Water Glue(Option hot melt glue system is additional for side gluing) |

| Paper Bag Bottom/Gusset | 60-130mm/2.36-5.12 inch |

| Working Speed | 40-75 pcs/min |

| Total Power | 20KW 380V 50HZ with 4wires 3phases |

| Machine Weight | 18T |

| Dimension(L× W× H) | 14000×5000× 3100mm |

DOWNLOAD:KL-220H.pdf

PRODUCTS DETAIL

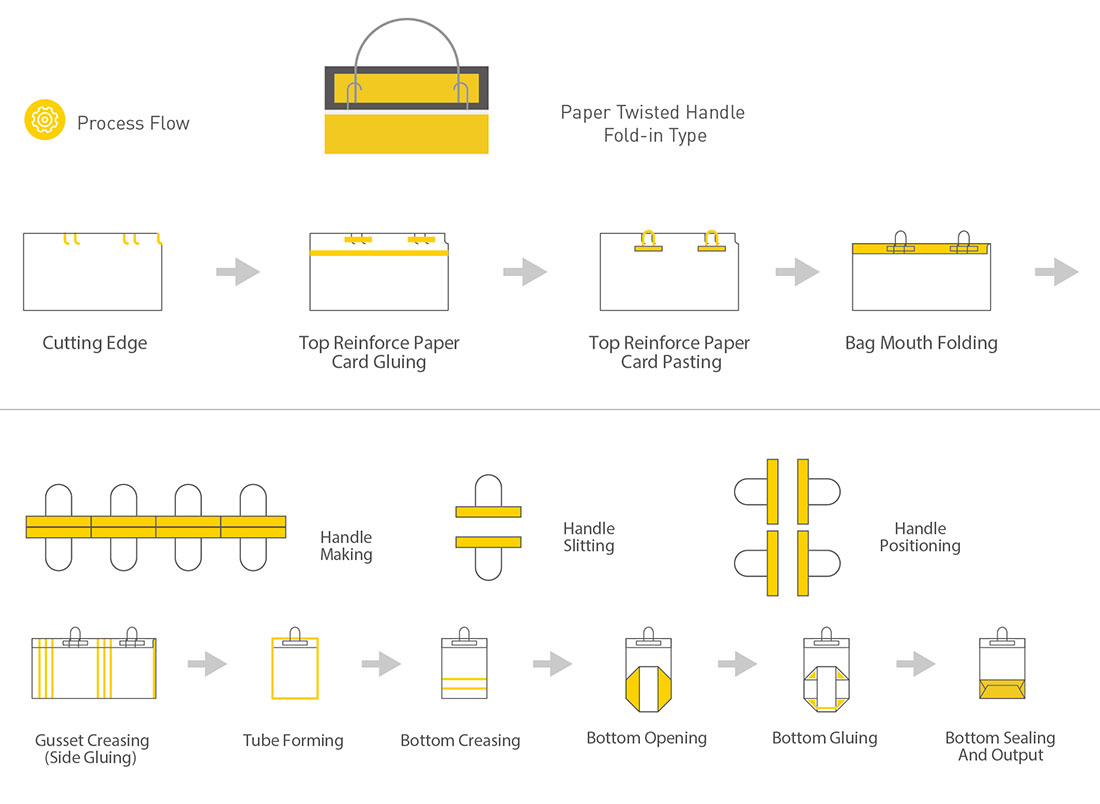

Working procedure

Fully Automatic Sheet Fed Paper Bag Machine With Paper Twisted Handle Inline

Note : Speed is determined by condtions such as air humidity, paper material, paper basis weight, paper tolerance, paper twisted rope,patch card material and glue type etc.

Video :

Loading the player...