X

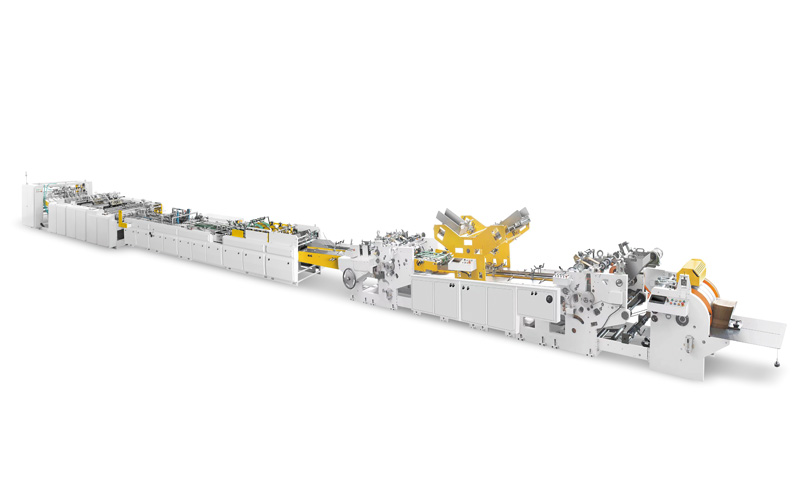

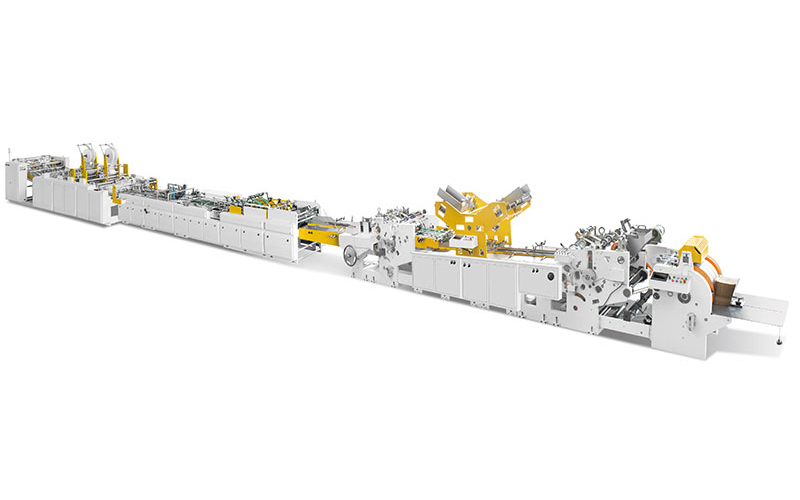

KL-350TB-S(Sheet type top cardboard pasting)

Main Technical Parameters

| Model | KL-350TB-S(Sheet type top cardboard pasting) |

| Paper Bag Width | 200-350mm |

| Paper Sheet Width | 530-1040 mm |

| Paper Sheet Length | 290-600mm |

| Paper Types/Paper Weight |

A .White / Brown Kraft Paper : 120-250g/m2 B.Art Paper + PP Laminating : 157-230g/m2 C. White Cardboard + PP Laminating : 150-250g/m2 D.Grey Paperboard + PP Laminating : 150-300g/m2 |

| Recommend that paper thickness above 200gsm die cutting before operation) | |

| Glue Type | Water Glue/Hot Glue Systerm |

| Top Reinforce Paper Roll Diameter | φ600mm |

| Top Reinforce Roll Paper Weight | 100-350g |

| Top Reinforce Roll Paper Width | 170-340mm |

| Top Reinforce Paper Cutting Length | 20-50mm |

| Paper Bag Bottom/Gusset | 70-150mm |

| Max.Bottom Reinforce Paper Card(W×L) | 144× 344mm |

| Min.Bottom Reinforce Paper Card(W× L) | 64×194mm |

| Bottom Reinforce Paper Card Weight |

150-400g |

| Working Speed | 40-60pcs/min |

| Punching Hole Spacing |

80-120mm Note: Above punching hole spacing are our standard parameters,which can be customized according to client's requirement. |

| Punching Hole Diameter | φ4 φ5 φ6mm |

| Total Power | 30KW 380V 50Hz |

| Machine Weight | 14T |

| Machine Dimension(L× W× H) | 23000×1930×1920mm |

DOWNLOAD:KL-350TB-S.pdf

PRODUCTS DETAIL

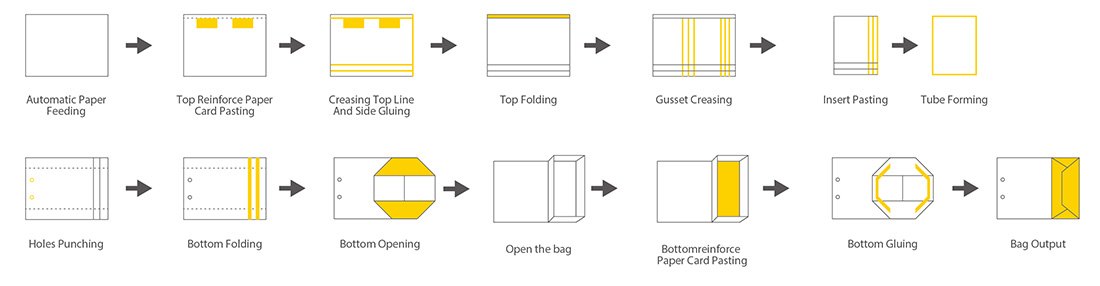

Working procedure

Automatic Paper Bag Making Machine Function With Both Top Reinforce Paper Card Pasting And Bottom Reinforce Paper Card Pasting

Note : The working speed varies with the paper type, paper weight, paper size, paper laminating or not, paper printing qulity, glue quality, air temperature and workshop environment.

Video :

Loading the player...